Manufacturing Process of ISO9809-3 Gas Cylinders

The manufacturing process of

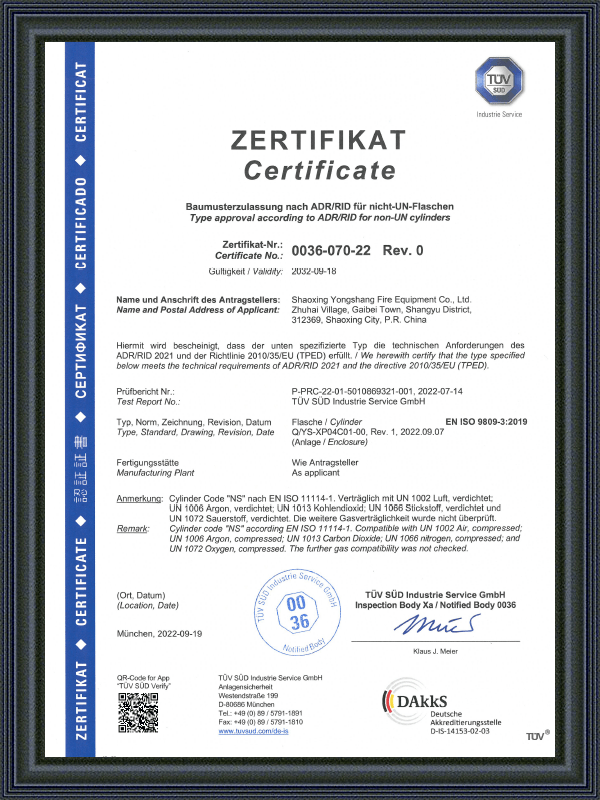

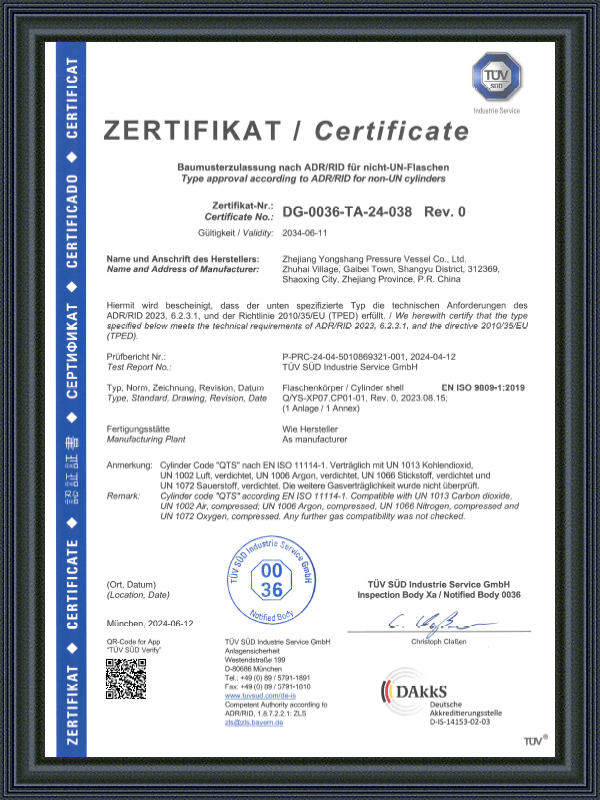

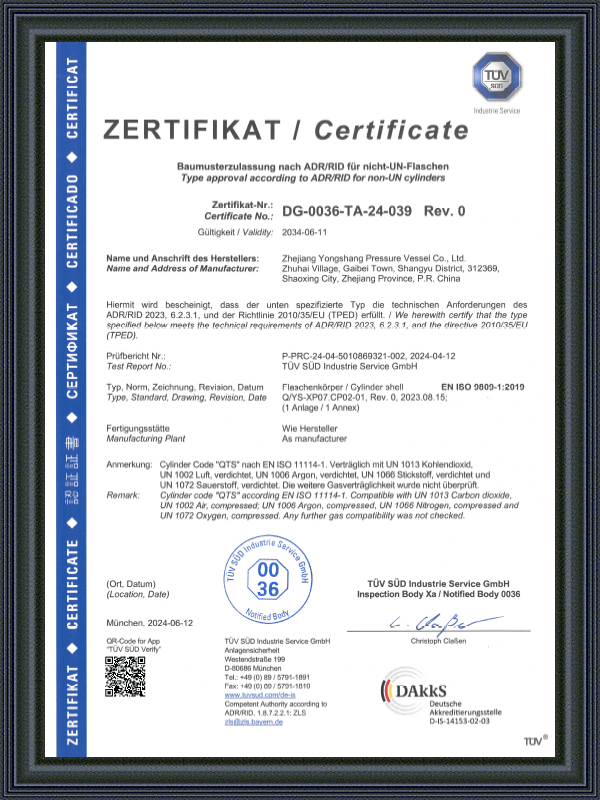

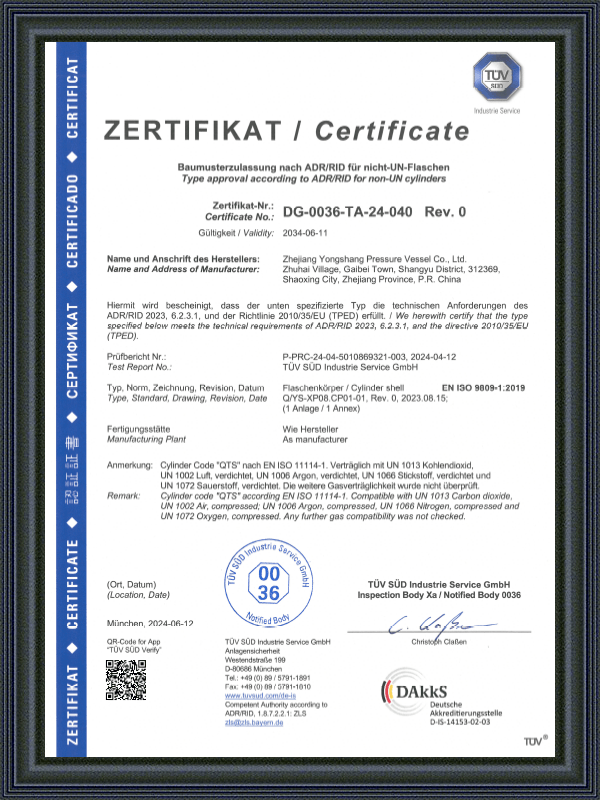

ISO9809-3 gas cylinders is a highly specialized and intricate procedure that requires strict adherence to international standards to ensure that the cylinders meet the required safety, quality, and performance criteria. ISO9809-3 is a widely recognized international standard that governs the design, construction, and testing of seamless steel cylinders used for the storage and transportation of compressed gases. The standard specifies the minimum requirements for the manufacturing process, ensuring the cylinders are durable, reliable, and safe under high-pressure conditions. Zhejiang Yongshang Pressure Vessel Co., Ltd., as a leading ISO9809-3 Gas Cylinder Manufacturer and Factory, employs advanced technologies and cutting-edge equipment to produce cylinders that not only meet but often exceed these standards.

The process of manufacturing ISO9809-3 gas cylinders begins with the careful selection of raw materials. The materials used must meet the strict specifications outlined in the ISO 9809-3 standard to ensure the cylinders’ strength and safety. High-quality carbon steel is typically the material of choice, as it offers the required strength-to-weight ratio while maintaining corrosion resistance under challenging conditions. The steel used must be free from impurities and defects that could compromise the integrity of the final product. Zhejiang Yongshang Pressure Vessel Co., Ltd. places a strong emphasis on sourcing the highest-grade steel from reputable suppliers, ensuring that the material meets international standards for pressure vessel construction. The steel is inspected before being used in production to verify its quality, chemical composition, and mechanical properties. This initial step sets the foundation for the entire manufacturing process, as the performance of the finished gas cylinder is directly influenced by the quality of the raw material.

The core characteristic of ISO9809-3 gas cylinders is their seamless construction. This is a critical factor in ensuring the structural integrity of the cylinder, as the absence of welds or seams minimizes the risk of weak points that could lead to failure under pressure. The seamless tube is produced using a process known as rotary piercing and elongation, which allows the cylinder to be formed from a solid billet of steel. The steel billet is heated to high temperatures in a furnace, making it malleable and easier to work with. The billet is then passed through a rotary piercer, which creates a small hole in the center of the billet. Once the hole is created, the billet is elongated by passing it through a series of rollers that stretch and thin the material into a hollow tube. The tube is then further drawn and elongated to reach the required length and diameter for the finished cylinder. This step in the process requires precise control of temperature, speed, and pressure to ensure that the tube is uniform in thickness and free from defects. The seamless construction of the tube allows for a uniform material structure throughout the entire cylinder, enhancing its strength and reducing the likelihood of stress points or failure under high pressure. Zhejiang Yongshang Pressure Vessel Co., Ltd. utilizes advanced extrusion and drawing technologies to ensure that each tube meets the exact specifications required by ISO 9809-3.

After the seamless tube has been formed, it undergoes a heat treatment process known as annealing. The purpose of this step is to improve the material’s mechanical properties, such as strength, hardness, and ductility. During annealing, the tube is heated to a specific temperature in a controlled environment, followed by a cooling process that helps to relieve internal stresses within the material. ISO9809-3 gas cylinders are designed to handle pressures up to 300 bar or more, depending on the gas being stored. By optimizing the microstructure of the steel through heat treatment, the company ensures that the cylinders possess the necessary tensile strength and toughness to withstand the mechanical stresses they will encounter during use. Zhejiang Yongshang Pressure Vessel Co., Ltd. carefully monitors the heat treatment process using advanced furnace technology and precise temperature control. The company’s expertise in heat treatment ensures that each cylinder achieves the desired balance of strength and ductility.

Once the tube has been heat-treated, it undergoes a series of machining and shaping operations to give it the final form of a gas cylinder. This includes cutting the tube to the required length and shaping the ends of the cylinder to prepare for the installation of the cylinder’s neck and valve. In this stage, Zhejiang Yongshang Pressure Vessel Co., Ltd. utilizes advanced CNC (Computer Numerical Control) machining equipment, which allows for high precision and consistency in the shaping process. This ensures that every cylinder produced adheres to the strict tolerances required by ISO 9809-3. The neck of the cylinder is also shaped to accommodate the valve and other fittings that will be installed in the next stages of production.

One of the most critical steps in the manufacturing process of ISO9809-3 gas cylinders is hydrostatic testing. This test involves filling the cylinder with water and pressurizing it to simulate the conditions it will face during use. The cylinder is subjected to internal pressure that is significantly higher than its rated working pressure to verify its structural integrity and ability to withstand high-pressure conditions without failure. Hydrostatic testing is essential for identifying any potential weaknesses or defects in the cylinder, such as leaks or cracks. The process ensures that the cylinder can safely store compressed gases at the required pressures without compromising safety. During the hydrostatic test, the cylinder is carefully monitored for any signs of deformation, leakage, or other issues that could affect its performance. Zhejiang Yongshang Pressure Vessel Co., Ltd. employs state-of-the-art testing equipment and procedures to conduct hydrostatic tests in accordance with ISO 9809-3 standards. The company ensures that every cylinder undergoes this rigorous testing process before it is approved for use, ensuring that customers receive a product that is safe and reliable.